We just lately had a dialog with LS Electrical, initially a part of the LG Group, started in 1974 as Fortunate Packing. In 2003, it separated from LG and have become a part of the LS Group, rebranding as LSIS. In 2020, LSIS adopted its present title, LS Electrical.

LS Electrical focuses on energy tools, automation methods, and options for energy vegetation, substations, and distribution networks. Their providers additionally embrace energy tools diagnostics and preventive upkeep methods.

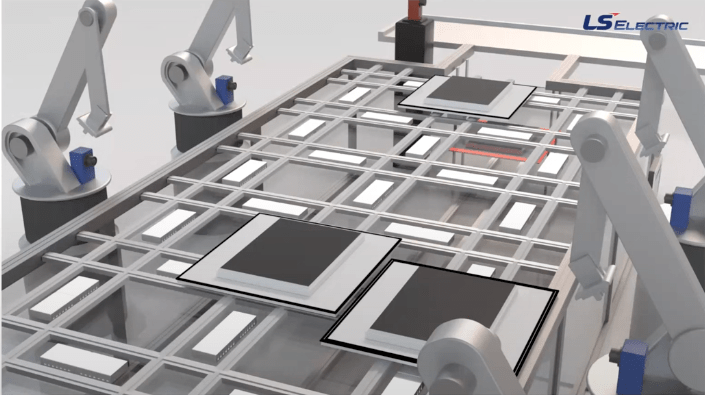

We explored their LS Sensible Shifting Administration System (SMMS) in our discussions with LS Electrical. This conveyor-belt substitute system makes use of a magnetic pressure as a substitute of conventional belts to maneuver objects alongside manufacturing strains.

The important thing good thing about SMMS is that magnetic pressure is utilized on to the item being moved—particularly, to palettes geared up with magnets—relatively than counting on a conveyor belt that strikes the whole line. Coils and sensors within the system induce magnetic forces to displace the palettes, enabling movement with a lot larger effectivity. This method permits palettes to maneuver vertically, creating multi-level manufacturing strains the place gadgets will be lifted or lowered between completely different paths.

Because the motion is contactless, the SMMS experiences much less friction and contamination than conventional conveyors. With out a transferring belt, the danger of conveyor-related accidents is considerably decreased. LS Electrical highlights that within the U.S. alone, conveyor belts are liable for round 9,000 accidents yearly, making security one among SMMS’s most vital benefits.

One other clear human security benefit is lowering mud, pollution, and lubricants within the workspace, due to eliminating belt friction.

Along with improved security, the absence of friction means an extended lifespan for the system, although extra knowledge is required to quantify this over time.

Past {hardware}, SMMS provides a formidable software program interface. Customers can customise manufacturing strains by a graphical drag-and-drop instrument. Some coding will be generated by a ChatGPT-powered interface, with built-in verification to make sure performance. The software program runs in a browser, permitting distant changes making it simpler for consultants to handle a number of websites or reply rapidly to points. Few industrial methods provide this user-friendly expertise, signaling a development towards extra accessible expertise on this sector.

LS Electrical notes that SMMS is energy-efficient, because it solely strikes the objects, not the whole manufacturing line. Whereas this declare is sensible in principle, we’re desperate to see extra knowledge when it turns into accessible. LS Electrical will likely be exhibiting its expertise at CES 2025.