[ad_1]

I’ve a 350 small block in my Mannequin A roadster that I’ve put plenty of miles on through the years. Just lately the mechanical gasoline pump give up on me so I changed it. Inside a few minutes of working with the brand new gasoline pump, gasoline began to shoot out of the vent tubes on my Q-jet carburetor. What would trigger this to occur and the way do I repair it?

W.H.

This can be a pretty widespread prevalence after swapping gasoline pumps. What occurs is the gasoline runs dry within the float bowl on the carburetor and within the gasoline line from the pump to the carburetor. Then once you exchange the gasoline pump with a brand new one, it instantly rushes gasoline from the pump by the road to the carburetor and into the float bowl.

This sudden rush of gasoline can knock filth and/or corrosion unfastened from the gasoline line after which carry it to the carburetor. Usually what is going to occur is that this particles will grow to be lodged between the needle and seat on the float system.

This particles will then stick the float within the down place and permit extra gasoline into the float. This extreme then will over-fill the float bowl and start dripping out of the boosters and flowing out the highest of the float bowl vent as you described.

Easy methods to Repair a Caught Q-Jet Float

The restore for a Q-jet is a little more concerned than for a Holley carburetor. With Holleys, usually you’ll be able to faucet within the needle and seat adjuster screw and typically this can dislodge the particles and clear the needle and seat. However most of the time, it’s going to require eradicating the needle and seat meeting from the carburetor and cleansing the particles.

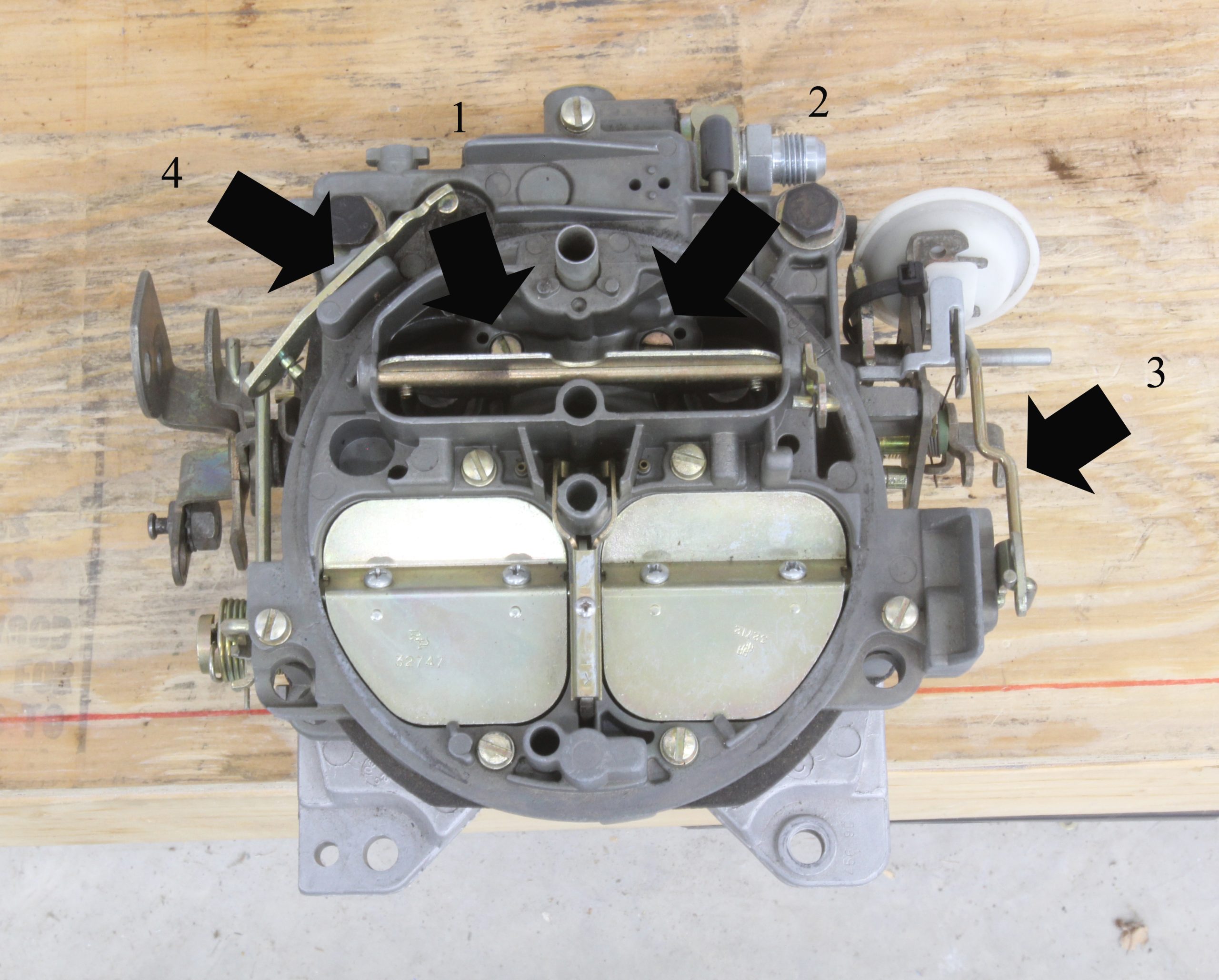

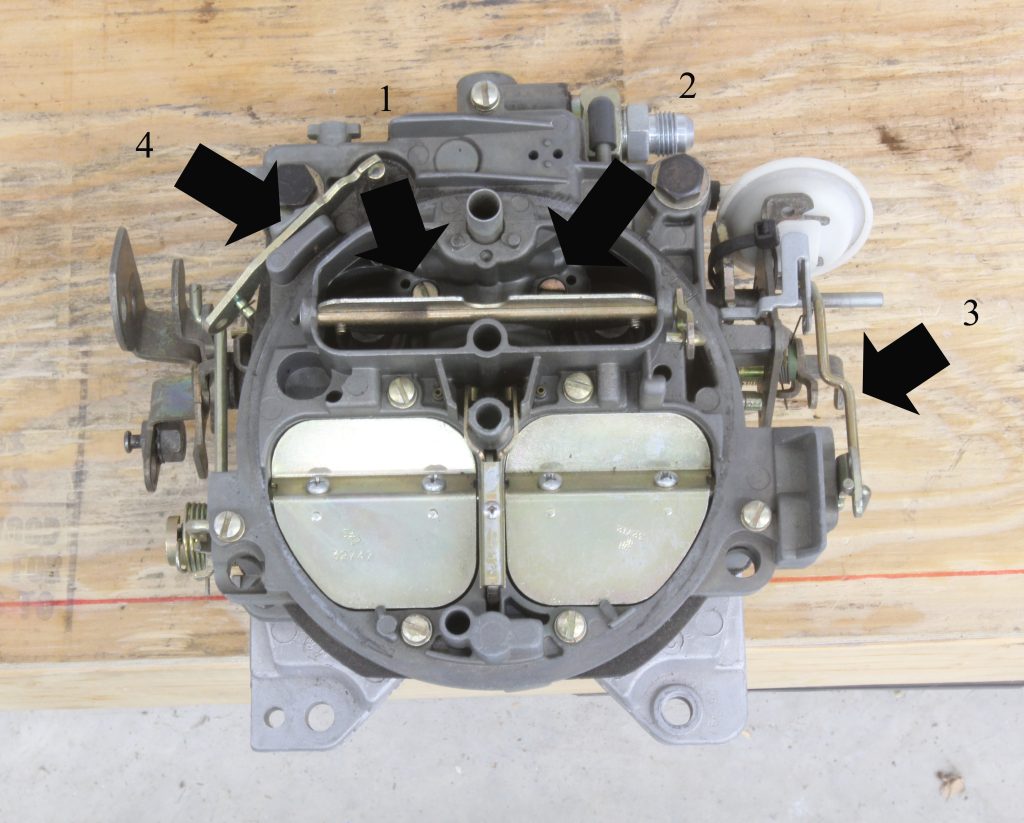

With a Rochester Quadrajet, the method of cleansing the needle and seat is similar but it surely requires rather more effort to entry the needle and seat as a result of the lid have to be eliminated to entry the needle and seat. The Q-jet has 8 small machine screws that connect the lid to the primary physique that have to be eliminated plus two 5/16 inch bolts that connect the carburetor to the consumption manifold.

Two of those small machine screws are hidden inside the first venturi and are simply missed. However earlier than you’ll be able to take away the carburetor lid, you could additionally drive out the roll pin that’s the pivot for the accelerator pump arm. The one method to drive the pin is with a really small pin punch that pushes the pivot towards the choke housing. Don’t drive the pin all the way in which towards the choke housing as this can make it rather more tough to slip the pin again in when re-assembling the carburetor.

Subsequent, additionally, you will need to take away the very small screw that holds the secondary metering rods in place. You may take away the lid with out eradicating the metering rod, however you’ll have to take away them to put in the lid.

Additionally, you will need to take away the arm between the secondary air valve door and the plastic secondary diaphragm to totally take away the lid from the primary physique of the carburetor. As soon as the lid is eliminated, you’ll be able to simply entry the needle and seat and clear out any particles. If the carburetor is just a few years outdated, it is perhaps a good suggestion to switch the lid gasket with a brand new one.

Or if the carb is crusty, this may be a superb time to take away the carburetor from the engine and rebuild the carb utterly Summit Racing affords two completely different JET Quadrajet rebuild kits, so the fitting equipment will rely on the 12 months of your Q-jet.

Eradicating the lid is a serious portion of the work to rebuild your carb, so a rebuild may not be a foul concept.

- JET-201004 – Quadrajet Rebuild equipment for “4M” Pre-Emission Carburetors

- JET-201003 – Quadrajet Rebuild equipment for “M4” Emissions-Period Carburetors

Different Issues to Think about

Earlier than re-installing the carburetor, it’s be a good suggestion to disable the ignition and place the gasoline line in a big container and pump about two or three pints of gasoline into the container. That is really useful anytime you exchange a gasoline pump to dislodge any particles and catch it within the container. If there isn’t any filth or crud within the container, then you’ll be able to re-install the gasoline line to the carburetor and you ought to be able to run.

Assuming the caught float has pumped a large quantity of gasoline into the consumption manifold, a lot of that gasoline will most likely discover its method into the oil pan previous the rings. It could be a god concept to vary the oil and filter earlier than working the engine. This may guarantee good lubrication particularly for the rings within the first couple of minutes of engine operation. It may also be a good suggestion to tug all of the spark plugs and spin the engine over to drive out any liquid gasoline. Your rings and cylinder partitions will thanks for this.

[ad_2]