[ad_1]

Having the proper wheelbase on the chassis and inserting the our bodies and hundreds within the correct place will guarantee that the axles are positioned accurately.

Are you aware how a lot truck weight issues? Let’s think about a situation the place a truck is constantly overloaded in regular use. This could result in numerous issues for each the customers and the tools installer. Overloads can considerably shorten the lifetime of a automobile and its parts, to not point out the potential non-compliance with weight legal guidelines and federal security requirements. For this reason performing a truck weight distribution evaluation is essential.

One of many most sensible and related facets of understanding a truck’s capabilities is its payload capability. However what precisely is payload capability? It is the utmost weight {that a} fleet can add to a truck’s cargo space, along with its curb weight, with out compromising security. This idea is essential for fleet managers and truck operators to understand.

NTEA members can benefit from the Affiliation’s “Car Heart of Gravity and Axle Weight Calculator” for extra assist.

What & Why of Truck Weight Distribution

What’s truck weight distribution, precisely? In easy phrases, truck weight distribution is the quantity of the overall automobile weight imposed on the next:

- Floor at an axle

- Group of axles

- A person wheel.

The burden on a truck should be distributed on the axles to adjust to the chassis producer’s axle rankings and weight legal guidelines.

A glossary of truck chassis dimensions.

Photograph courtesy of NTEA

Having the proper wheelbase on the chassis and inserting our bodies and hundreds within the correct place will make sure that axles are loaded accurately and that payload capability is just not maxed out. A truck weight distribution evaluation is carried out to determine the correct axle loadings earlier than constructing a truck.

Axle capacities are restricted both by the axle capability or authorized weight limits, whichever is decrease.

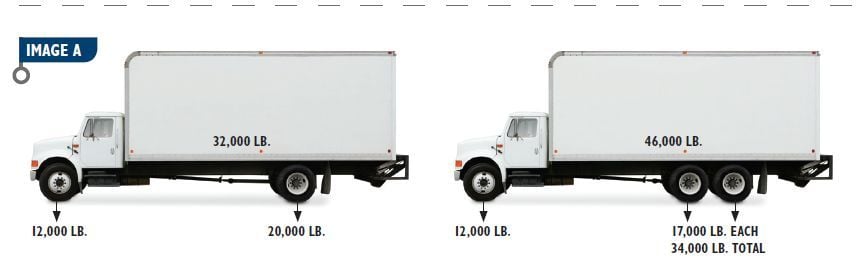

Each vans in Picture A have a entrance axle rated at 12,000 lbs., limiting the burden on these axles. The rear axle on the single-drive truck is proscribed by the axle capability or authorized weight restrictions to twenty,000 lbs. The 2 rear axles on the tandem-drive truck are restricted both by axle capacities or authorized weight restrictions to 17,000 lbs. for every axle, or a complete of 34,000 lbs. for the pair of axles.

What’s the Impression of a Truck’s Heart of Gravity?

Whereas the idea of an object’s middle of gravity is one thing many people really feel assured in understanding, let’s delve deeper into it. Think about you are making an attempt to determine the middle of gravity on an odd-shaped object. What about one thing like a truck, contemplating the burden of the engine, axles, and loaded or unloaded trailer? It is not as easy because it appears, however understanding this idea is essential for sustaining your truck’s stability and security.

The middle of gravity of an object doesn’t should be within the materials of the thing (Picture C). When contemplating a strong ball, similar to a billiard ball, it’s apparent the middle of gravity is the middle of the ball and within the materials that makes up the thing.

Within the case of a hole ball, the middle of gravity can be on the middle, however it isn’t within the materials. If the middle of gravity of a truck physique is within the materials of the physique, it’s a coincidence. More often than not, the middle of gravity of a truck physique is within the air, much like the hole ball instance.

The centers-of-gravity of the truck chassis is proven on the prime of the body rail on the cab and physique and cargo centers-of-gravity are proven with a single image on the middle of the physique a few third of the physique peak above the ground.

Photograph courtesy of NTEA

Every truck element, together with passengers and cargo, have a middle of gravity. For instance, the middle of gravity of the truck chassis is proven on the prime of the body rail behind the cab and the physique and cargo facilities of gravity are proven with a single image on the middle of the physique a few third of the physique peak above the ground.

The horizontal facilities of gravity are used to calculate weight distribution on the axles. If particular person wheel loadings are calculated, the lateral facilities of gravity are additionally used. Until a lateral middle of gravity is given for the chassis or a element, it’s assumed to be on the centerline of the chassis.

The horizontal and vertical facilities of gravity for your entire pattern truck is proven with the middle of gravity (CG) image.

Photograph courtesy of NTEA

Lateral facilities of gravity (CGs) are measured from the automobile centerline towards the appropriate or passenger facet as optimistic, left as unfavourable. These are used to calculate particular person wheel loadings and in-compliance calculations.

“Moments” are a strategy to measure the pressure or weight of an object. It is calculated by multiplying the pressure or weight by the gap it is utilized. For instance, one pound of pressure occasions one foot is 1 ft.-lb. One pound of pressure occasions 12 inches is 12 in.-lbs. They’re each the identical second. Understanding this idea is important for calculating weight distribution and making certain the protected operation of your truck.

Moments can be utilized to calculate:

- CGs.

- Weight distribution.

- Body hundreds.

- Hoist capacities.

- Efficient wheelbase.

Moments present a strategy to mix a lot of parts or objects to calculate a CG for them as a gaggle (Picture F).

When the CG distance is understood for all objects mixed, it’s attainable to calculate the burden on every axle. Moments in a single route should match the moments within the different. The down second of the chassis plus the down second of the physique should equal the up second on the rear axle. This stability is essential for sustaining your truck’s stability and making certain its protected operation.

Lateral CGs measured from the automobile centerline with towards the appropriate or passenger facet as optimistic. Towards the left is unfavourable. They’re used to calculate particular person wheel loadings and inccompliance calculations.

Photograph courtesy of NTEA

The Truck Weight Distribution Evaluation Course of

If you wish to know how one can calculate truck weight distribution, use the next 4 steps:

- Decide the truck weight and middle of gravity location for all the parts and objects to be thought-about

- Multiply the middle of gravity distance occasions the burden to get the second for every element and merchandise.

- Add all the moments and divide by the wheelbase to get the burden on the rear axle.

- Subtract the rear axle weight from the overall weight to get the entrance axle weight.

When the CG distance for all the objects mixed, you may calculate the burden on every axle.

Photograph courtesy of NTEA

Glossary of Truck Weight Phrases

AF – (After Body). The space from the middle of the again axle to the rear finish of the chassis body.

BA – Bumper to axle

BL – (Physique Size). Total size of the physique.

CA – (Cab to Axle). Distance from again of the cab to middle of the rear axle.

CB – (Cab to Physique). Distance between again of cab to entrance of physique.

GVWR – Gross automobile weight ranking

WB – (Wheelbase). Distance from middle of the entrance axle to middle of rear axle.

Why Does Truck Weight Matter?

Backside line: the burden of a truck issues in truck fleet administration and operation. A heavier truck with a 5,000-lb. GVWR can’t carry as a lot payload as a lighter truck with the identical 5,000-lb. GVWR, it is basic math. Moreover, when unloaded, a lighter truck makes use of much less gas than a heavier counterpart.

Some further methods to cut back weight embody the supplies your truck is made out of. As beforehand reported right here in Work Truck: Lowering the burden of the truck lowers the automobile’s middle of gravity, resulting in elevated maneuverability and a tighter turning radius. Much less weight additionally means superior acceleration and braking. This not solely results in a snug driving expertise but additionally higher gas mileage, because the truck is getting up to the mark and stopping quicker.

A lighter truck permits for better hauling capability. As a result of work vans should abide by weight restrictions, a heavier truck means lighter hundreds, much less effectivity, and misplaced {dollars}.

Interested by how one can light-weight your truck fleet? Or what influence the added weight of an electrical battery has on a truck’s suspension? Learn extra now and join our Work Truck eNewsletter so that you by no means miss a useful resource in your industrial fleet operation!

Editor’s Word: This text was initially revealed in 2011 and has been reviewed and up to date for continued relevance.

Initially posted on Work Truck On-line

[ad_2]