[ad_1]

We rebuilt a brand new 5.3L LS engine for our 1954 Chevy truck with a 4L60E computerized behind it. We added a efficiency cam and had the oil pan off to scrub the engine and examine the whole lot and add new gaskets.

As soon as we had the engine within the truck and working the converter, the entrance pump seal failed immediately inside lower than 100 miles. The transmission was used so we figured it was only a unhealthy seal. We changed the entrance pump seal however inside one other 100 miles it began leaking once more. We’ve regarded it over and may’t determine what we’re doing unsuitable.

We don’t need to simply put one other seal in it—clearly there’s an issue. Any concepts?

J.F.

We’d have provided a bunch of concepts round this, however fortunately (or unluckily), this has occurred to a buddy of ours who was scuffling with a really related downside.

There are probably different points right here however we’ll deal with the one which we found with our buddy’s transmission in a 2007 Chevrolet Tahoe with a 5.3L LS engine and 4L60E transmission.

Understanding the LS Oil Pan Design

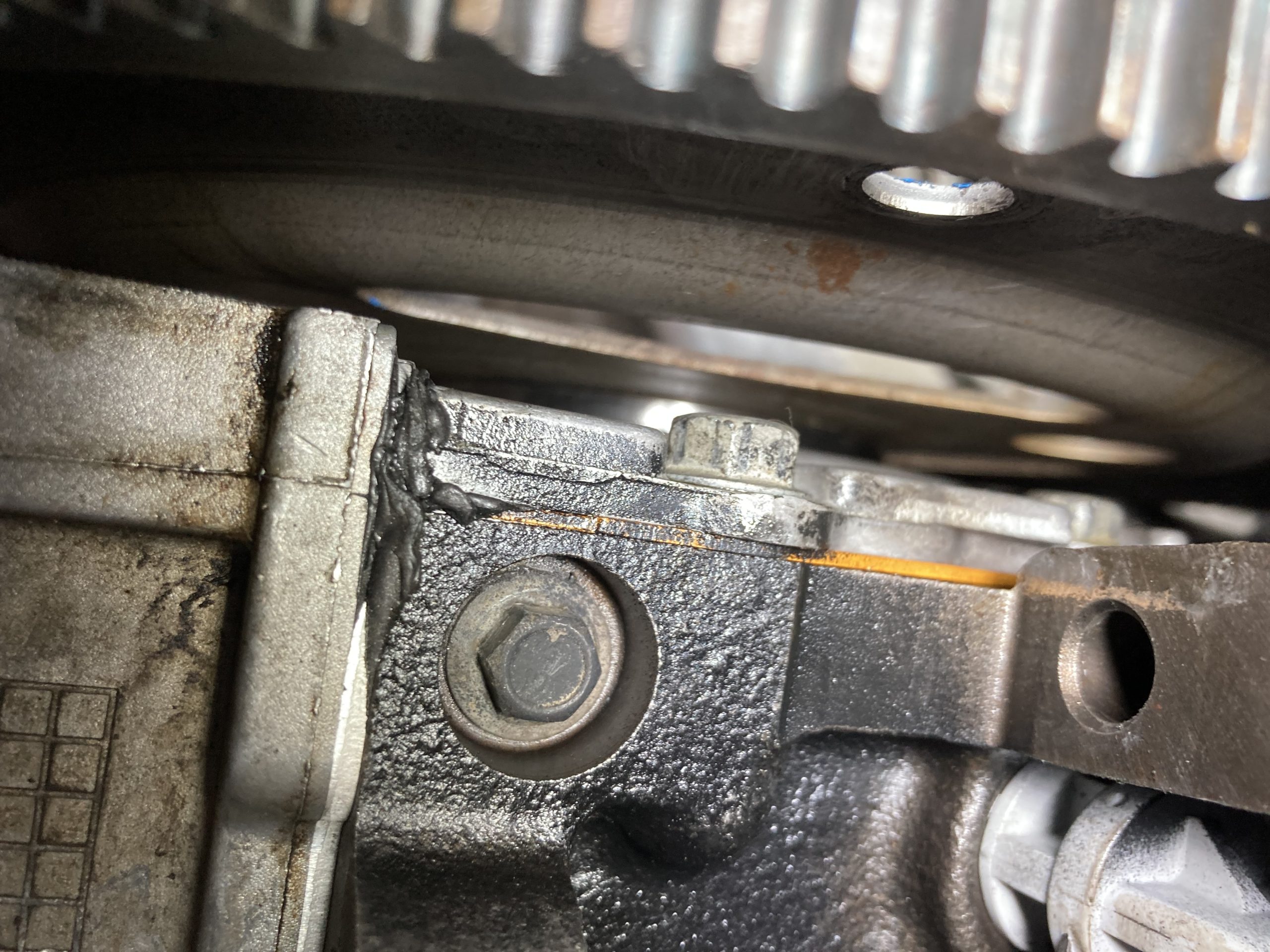

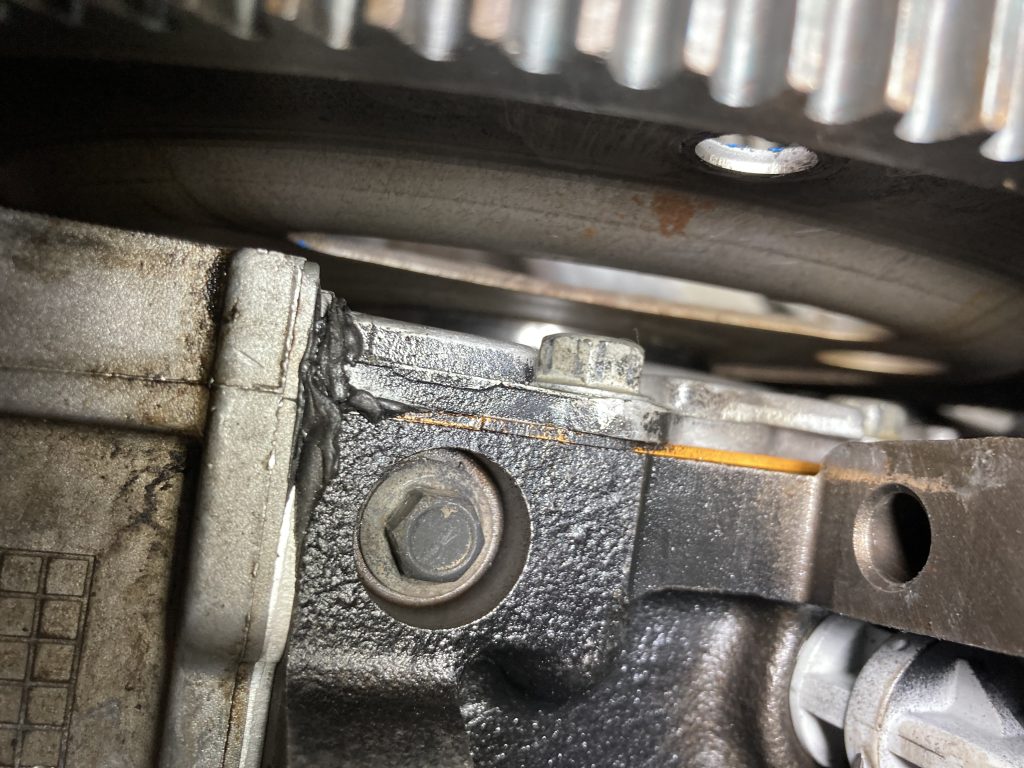

To ensure that this to make sense, it’s good to know that when GM designed the LS engine, they built-in the forged aluminum pan as a part of all the drivetrain bundle. What meaning is that, on the backside of the oil pan, GM included two threaded bolt holes within the oil pan the place the underside of the total face bellhousing bolts to the pan. GM did this to enhance the power of the connection between the transmission and the engine.

That is important to what typically occurs with modifications to those engines and transmissions. The difficulty lies with correct alignment of the oil pan with the again of the engine. The LS engines will not be fitted with dowel or alignment pins to place the entrance or rear cam covers, nor are there dowel pins for the oil pan.

All these elements primarily “float” on or across the block’s oil pan rail.

It’s very simple to place the oil pan barely rearward of the vertical bellhousing flange on the LS engines. If this happens and the transmission is bolted to the engine, this slight misalignment of the rear vertical pan face to the transmission bellhousing will tilt or cock the decrease portion of the bellhousing rearward. If the pan is misaligned far sufficient rearward, it can impart a load on the entrance of the transmission which is able to create a lateral load on the transmission enter shaft via the converter.

What occurs is the converter and crankshaft are now not correctly aligned and this misalignment can put a lateral load on the converter which is able to fail the entrance pump bushing and seal in a short time.

Checking & Fixing the Leaky Transmission Seal

One technique to examine that is to take away the transmission and place a small block Chevy fashion handbook transmission bellhousing on the again of the engine and see if the forged aluminum oil pan pushes the bellhousing face rearward. In our buddy’s scenario, the bellhousing really rocked vertically across the alignment dowels that instructed us the oil pan was too far rearward. You might even see this as a niche between the bellhousing and engine’s bellhousing mounting floor.

The repair for that is easy. You’ll have to loosen all of the oil pan bolts and pry the oil pan ahead sufficient to relocate it to be as near parallel with the bellhousing flange as doable.

It will permit the automated transmission bellhousing flange to then align correctly to the engine. If the oil pan is mounted too far ahead, the alternative however equally problematic subject will happen the place this once more places a load on the converter seal as a result of the trans shouldn’t be vertically aligned. This makes oil pan placement crucial.

After all, in case you are utilizing an aftermarket metal or aluminum sheetmetal LS oil pan, this gained’t be a problem. However when utilizing even an aftermarket oil pan just like the Holley forged aluminum LS oil pan, these pans are machined for the decrease bellhousing bolts and the pan have to be correctly aligned or the issue will floor many times..

[ad_2]