[ad_1]

Ford’s 351 Cleveland V8 is a legend in American excessive efficiency. A pleasant compromise between a small block and an enormous block, fans like it for its brute demeanor and talent to make plentiful energy.

Nevertheless, there’s quite a lot of fable and folklore surrounding the 351C’s improvement. We lately had a dialog with retired Ford engineer Invoice Barr, who was there to see all of it. He set quite a lot of the misconceptions to relaxation concerning the Cleveland.

Barr labored in Ford engine improvement and engineering for many of his profession. He managed Ford’s FE large block program, together with improvement of 428 Cobra Jet. He additionally labored on the 1969-70 Boss 302 engine program.

Nobody, together with different profession Ford engineers and product planners we’ve spoken with, may keep in mind the place the 351C originated. Barr instructed us the engine was conceived in Ford’s Superior Engines unit—one thing of a secretive “Skunk Works” throughout the firm. The plan was to scale the variety of Ford V8 households down to simply two—one small block and one large block. The massive block turned the 385 Sequence 429/460. The small block was named the 335 Sequence. Preliminary displacement was set at 335 cubic inches, however that was up to date to the 351 and 400 CID engines we’re accustomed to.

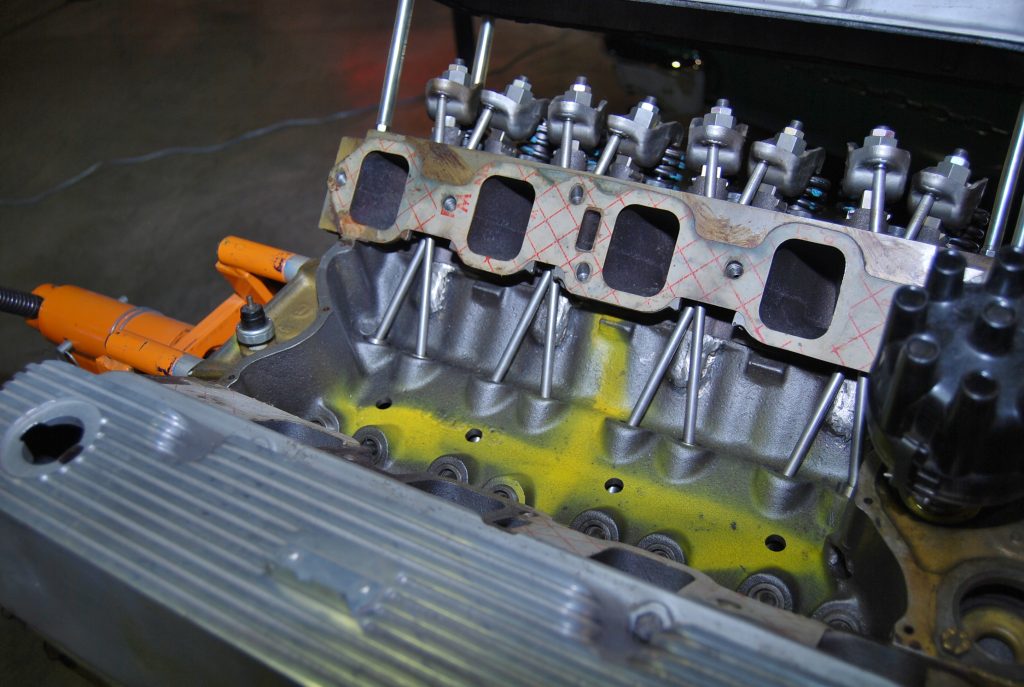

Ford’s unique sport plan for the 335 Sequence was to construct a V8 engine with fewer potential leak factors and extra good mating surfaces, wider essential bearing journals, and higher gasket/sealing expertise. Ford engineers believed the 351C had fewer potential leakage factors because of a metal plate timing cowl, a greater relationship between the oil pan and block, and a cooling system that bypassed the consumption manifold fully. Coolant flowed throughout the block as a substitute of by the induction system, which diminished or eradicated leaks and diminished induction temperatures.

Barr admits he hated the 351C. It made little sense to him as a seasoned Ford engineer who understood engine structure and the place this engine fell brief. It was too heavy for one factor. The oiling system is without doubt one of the worst in Ford’s historical past with oil hunger points which have plagued racers and efficiency fans for many years. Nevertheless, Barr cherished the 351C’s cylinder heads and tailored them for the Boss 302. Extra on that.

Smokey Yunick and the Indy Engine

Right here’s one other twist to the 351C story. In 1968 Ford’s then President, Semon E. “Bunkie” Knudsen, requested racing legend Smokey Yunick to assist develop an engine for Indy competitors. Yunick had an extended and profitable historical past with Basic Motors together with enter on Chevrolet’s Mark IV large block launched in 1965.

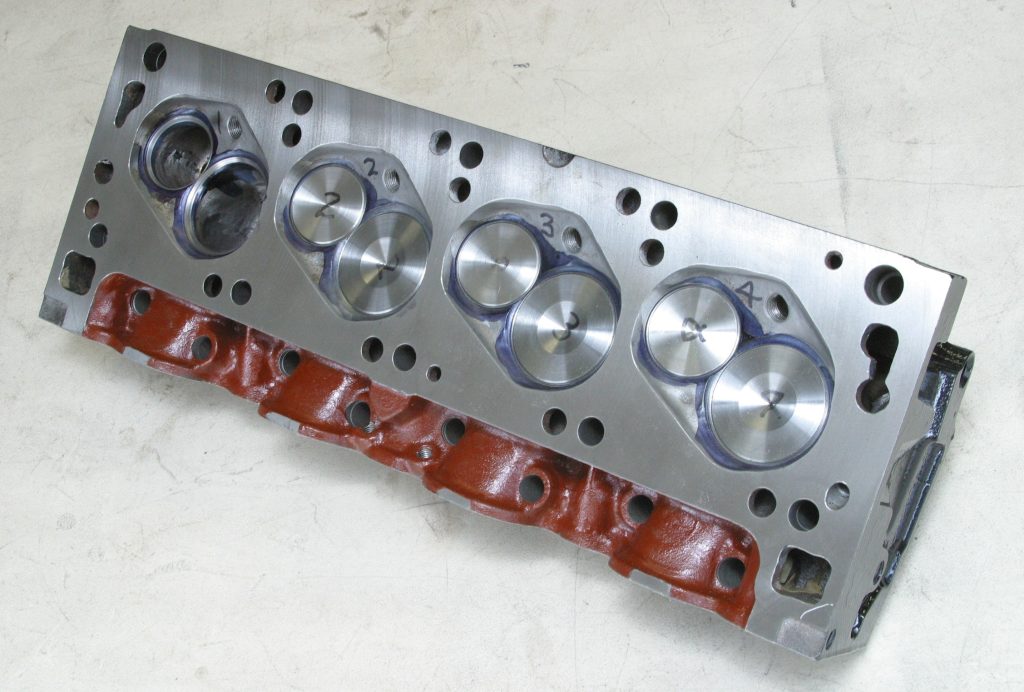

Ford’s prototype Indy engine was similar to the manufacturing 351C. It had a skirtless block and the identical bore and bolt-hole spacing because the 289/302/351W small block. The heads had poly-angle valvetrain geometry with angled pushrods that crisscrossed over each other and ports even bigger than the 351C-4V castings. The Knudsen/Yunick-inspired Indy Cleveland went the best way of Knudsen himself when he was fired by Henry Ford II in 1969 for failure to adapt to the Ford tradition. However a lot of the expertise was used within the manufacturing 351C. Now you realize.

The BOSS 302/351C Connection

The 1969-70 BOSS 302 engine was developed within the wake of the ill-fated 302 “Tunnel Port” small block of 1968. Constructed for SCCA Trans-Am competitors, the Tunnel Port was a catastrophe. The engine didn’t make peak horsepower till 8,000 RPM, which led to catastrophic engine failures and embarrassing losses. Racers have been scattering Tunnel Ports throughout racetracks through the 1968 season.

When our engineer good friend Invoice Barr discovered of the excessive Tunnel Port failure charges, he started looking for fast solutions throughout the firm. As talked about earlier, he discovered an appropriate answer at Ford Superior Engines’ 335-Sequence program. He borrowed a pair of 351C cylinder head castings and went to work. The bolt sample and bore spacing have been the identical between the small block and the 351C so the heads would bodily bolt on. Barr did must have particular pistons made. He additionally revised coolant move by the Cleveland heads so they might work with the “moist” consumption manifold of the 302 engine. Thus, the Boss 302 was born. Ford’s SCCA-Trans Am wins in 1969-70 and the desirability of the Boss 302 Mustang avenue automobiles converse for Barr’s wonderful work.

The 351M and 400

The 351C had two cousins. The raised-deck 400 CID engine changed the 390 and 428 FE large block engines in 1971. It had 4.000-inch bores and a 4.000-inch stroke to create a “sq.” bore/stroke ratio—in different phrases, an engine large on torque to drag round F-Sequence vehicles and full-sized Fords and Mercuries. Ford by no means recognized the 400 because the 400C or 400M. It was at all times identified throughout the firm as plain previous 400.

After Ford ended 351C manufacturing in 1974, it determined to make a brand new 351 cubic inch engine by destroking the 400 to three.500 inches. Designated 351M (Modified), it was a bean counter brainstorm conceived to cut back manufacturing prices. Nevertheless, it was a horrible thought since you had much less displacement and energy in an engine that weighed the identical because the 400.

Each the 351M and 400 got here with a 429/460 large block bellhousing bolt sample, although early manufacturing 400 engine blocks have large block and small block bell patterns. Each engine used the 351C-2V heads with open chambers, which have been liable to detonation points.

Though the 400 and 351M engines get quite a lot of criticism, there’s extra to those engines than you see on the floor. The 400 may have been factory-grown to 430 to 450 CID, making a ‘mid-sized’ engine with a big-block persona with out the burden penalty. That is one thing you are able to do your self with a stroker equipment.

Get extra information on Ford’s 351s in What’s the Distinction Between a Ford 351 Windsor, Cleveland, or Modified Engine?

What’s In A Title?

The ”Cleveland” title for the brand new 335 Sequence engine resulted from an id disaster in Ford vendor service departments and automotive restore outlets. Ford already had the 351W, which was a raised-deck 289/302 engine with 4.000-inch bores launched in 1969 to compete with GM’s 350/400 cubic inch engines. When the 351C arrived in 1970, there was confusion among the many service technicians although the 2 engines have been vastly completely different in look and simply recognized.

Ford issued a Technical Service Bulletin addressing 351 CID V8 engine identification. As a result of the 351W was produced primarily at Ford’s Windsor, Ontario foundry and engine plant throughout the river from Detroit, it will be often known as the 351 “Windsor”. The 351C was forged and assembled on the Cleveland foundry and engine plant in Brook Park, Ohio, so it turned the 351 “Cleveland”.

Enjoyable truth: The 351C was manufactured utilizing a brand new sizzling testing course of on the Cleveland plant. The engines have been fired in a “merry-go-round” course of earlier than they have been shipped to Ford meeting crops.

The 351C in Australia

The 351C was launched in Australia on the similar time it was supplied in North America. To start with, Australian Falcons have been fitted with 351C engines produced at Ford’s Cleveland engine plant. Blocks have been additionally forged at Cleveland and shipped to Australia. Sooner or later, Ford Australia started producing full 351C engines together with destroked 302 cubic inch Clevelands. The engines have been produced from 1972 to 1982.

Right here within the States, Ford packaged the 351-4V heads with small wedge chambers and big consumption ports. These labored properly at excessive RPM however weren’t the best on the road the place low-end torque was extra essential. The Aussies gave their Cleveland cylinder heads the smaller 61-64cc combustion chambers from the 4V heads and the smaller 351C-2V ports for good avenue torque. The 302 sported a unique head fully with smaller 57-61cc wedge chambers.

As a rule, Aussie Cleveland castings don’t have Ford North America casting numbers. For those who discover a Cleveland block with no North American casting quantity and a “GF”(Geelong) foundry designation, you’ve discovered an Australian block. Nevertheless, some consider North American molds have been shipped to Geelong to make the primary Aussie castings, which implies there might be some with North American Ford casting numbers. One other perception is Ford North America shipped discontinued Cleveland casting molds to Australia in 1974 when manufacturing ended within the States.

Only a few manufacturing Australian 351C blocks had four-bolt essential caps. These fitted with four-bolt essential caps have been both transformed or have been experimental blocks.

[ad_2]