[ad_1]

Why do individuals select the bigger 6.0L over the smaller 4.8L and 5.3L in terms of time to make energy?

Why is the bigger motor costlier and tougher to seek out in wrecking yards? Principally, why is the 6.0L higher than its smaller siblings?

The reply is energy!

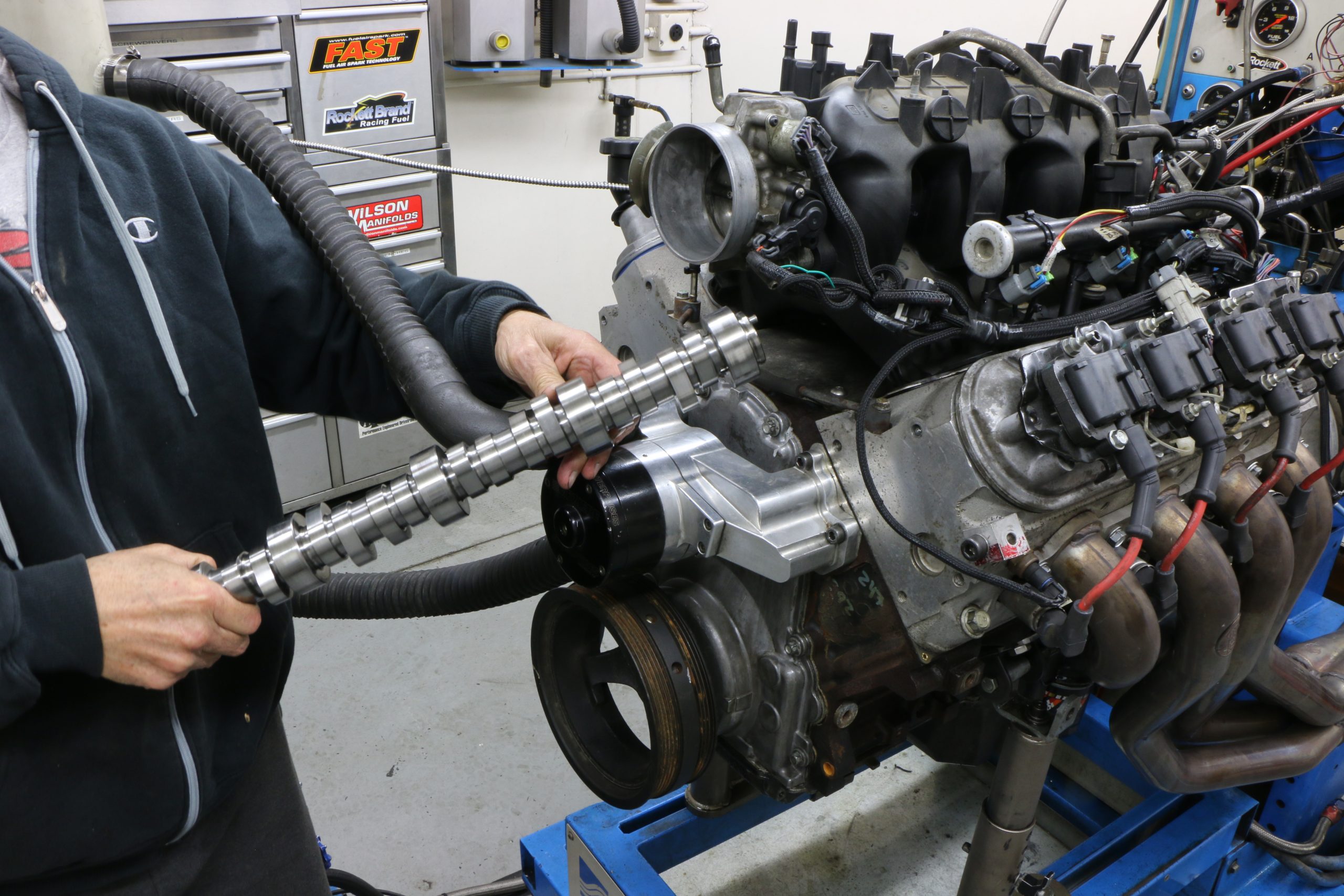

Greater motors flat out make extra energy, and never simply extra peak energy, however extra common energy. Peak numbers are all effectively and good, however what actually makes a mix profitable is extra energy via your entire rev vary. In comparison with the smaller 4.8L and 5.3L motors, the 6.0L not solely makes extra peak horsepower and torque, it additionally makes extra energy from off idle all the way in which to redline.

Having extra common energy interprets on to faster acceleration. It may possibly additionally translate into improved towing energy or heck, an excellent, old-fashion smoke present! No matter your wants, a much bigger motor could make it occur sooner.

However simply because you have got the larger 6.0L, doesn’t imply you’ll be able to’t make it higher. In spite of everything, the one factor higher than a inventory 6.0L is a modified one, so let’s check out three completely different NA 6.0L builds, starting from delicate to wild, together with a inventory LQ4.

400 Horsepower 6.0L LQ4

To achieve the 400 (flywheel) hp mark, we have to first perceive the distinction between rated and examined energy output.

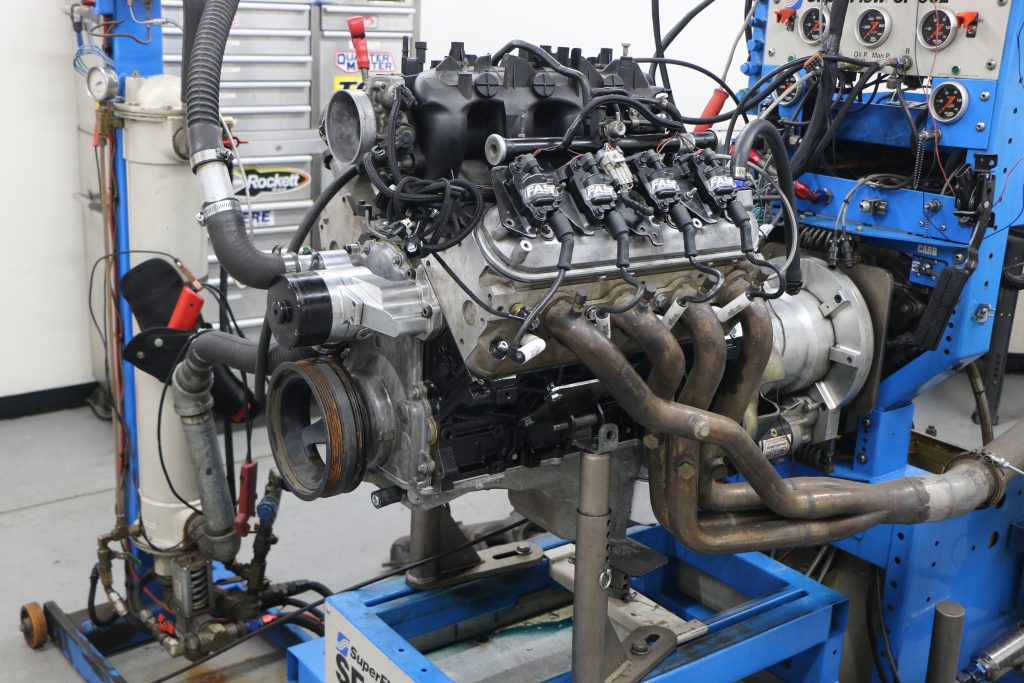

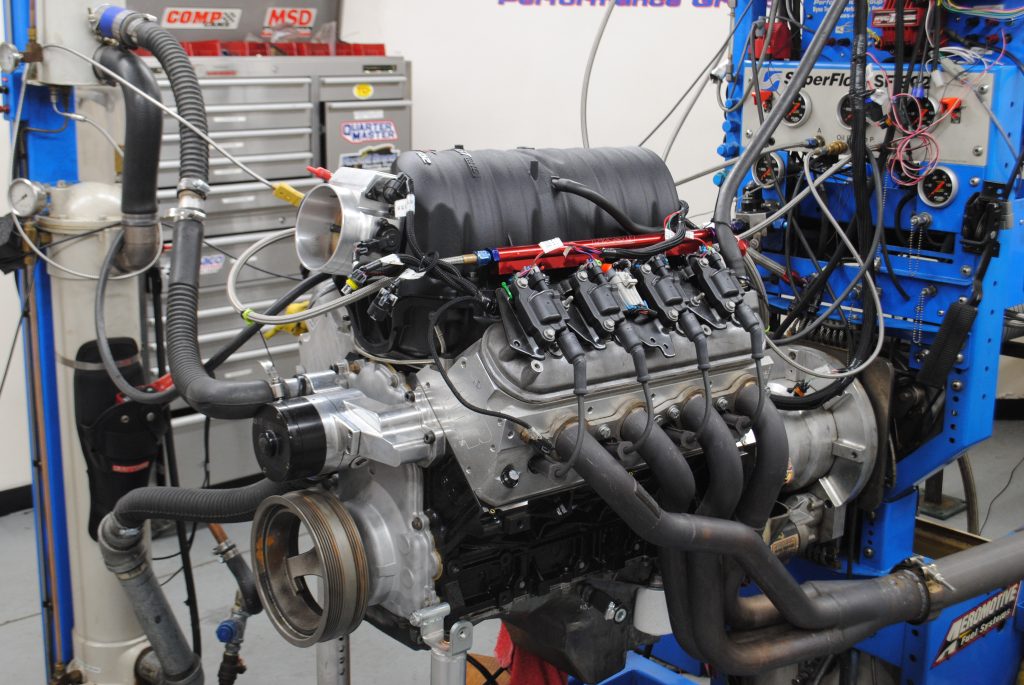

The GM manufacturing facility (flywheel) ranking is run in inventory trim, at regular working temperature, with full exhaust and air consumption, with full equipment and the manufacturing facility (non-optimized) tune. On the engine dyno, we examined the “inventory” rebuilt 6.0L LQ4 in a distinct configuration, because the LS was run with no equipment or air consumption, with long-tub headers and three inch exhaust and with an optimized tune (and colder).

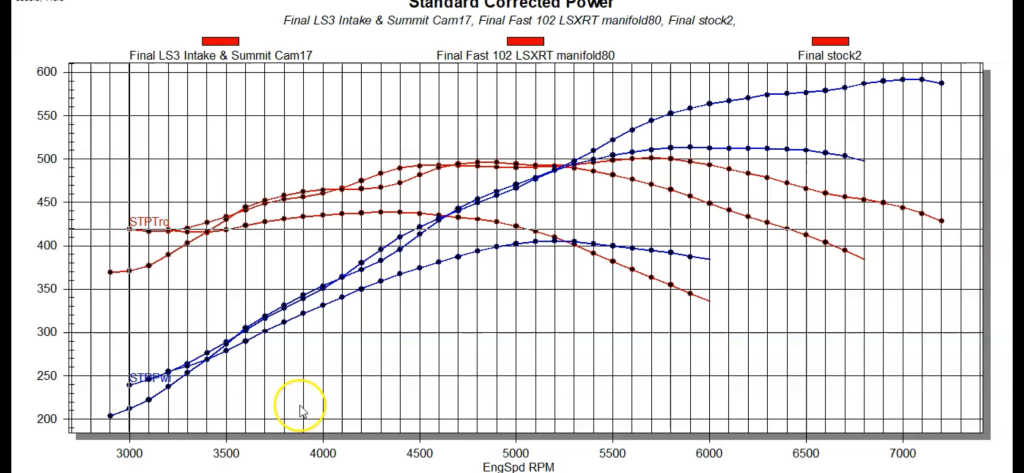

These modifications launched extra energy from the 6.0L, which is why our “inventory” LQ4 made extra energy than the rated output (which varies with yr and utility). The junkyard 6.0L was given an overhaul, with a ball hone, new rings and bearings, and a recent valve job on the 317 heads. The LQ4 was geared up with the later LQ4/LQ9 cam (early fashions shared the smaller LM7 cam), the inventory early truck consumption and throttle physique and run with a Holley HP administration system controlling 80 pound injectors (used for later testing).

Run on this method, the LQ4 produced 402 hp at 5,200 rpm and 438 lb.-ft. of torque at 4,300 rpm.

The 400 hp 6.0L truck motor did precisely what we anticipated, making peak energy low within the rpm vary to boost torque manufacturing, however how will we now get much more energy out of a 6.0L?

500 Horsepower 6.0L LY6

On condition that the inventory LQ4 made proper at 400 hp and 438 lb.-ft., what does it take to get a 6.0L to succeed in the 500-hp mark?

The reply, as all the time with LS motors, is a cam swap.

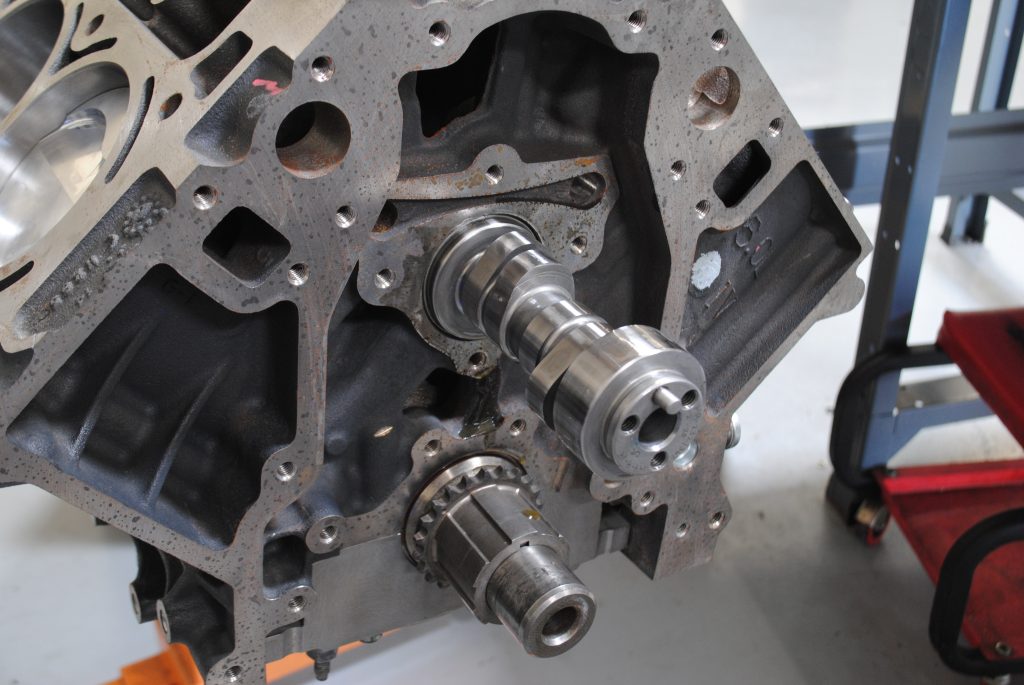

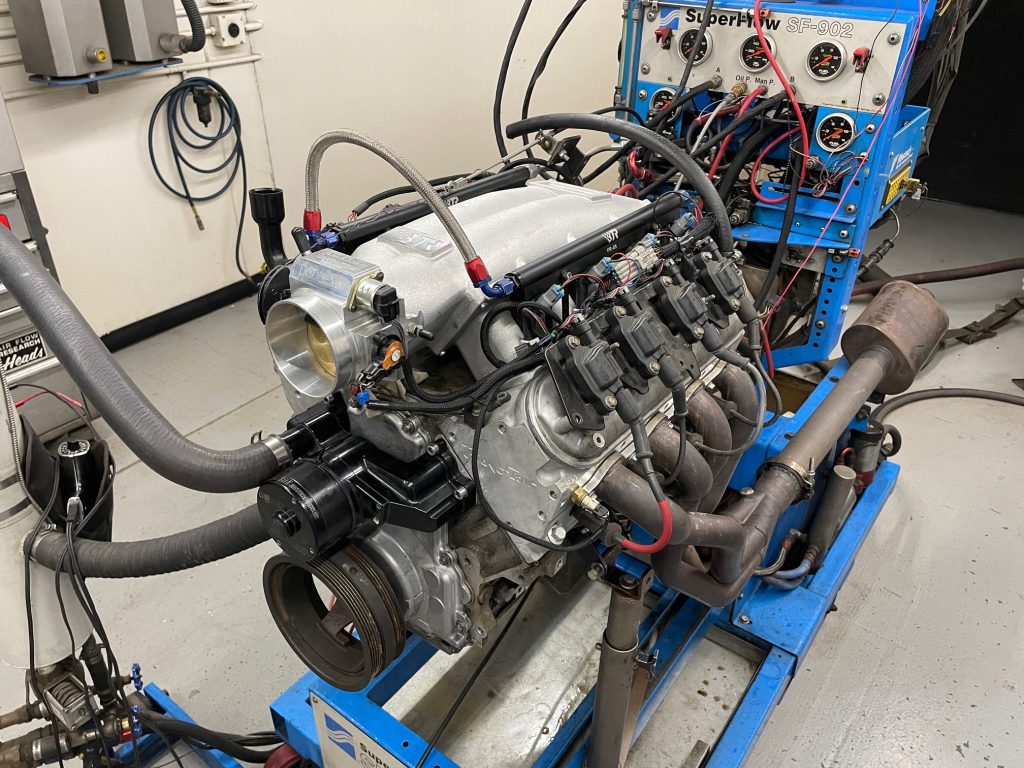

In reality, this 6.0L combo additionally benefitted from extra head circulate, as we began this construct up with an LY6 6.0L as an alternative of an LQ4/LQ9. The LY6 began out life with rec-port (LS3) heads and variable valve timing (VVT) and an equally good rec-port consumption manifold. Exceeding 500 hp solely required changing the manufacturing facility VVT cam with (on this case) and Trick Movement model of the well-known Sloppy Stage 2 cam. That cam from TFS supplied 0.585 elevate, a 228/230 diploma period break up, and 112 diploma LSA. The cam was mixed with a dual-spring improve from Brian Tooley Racing.

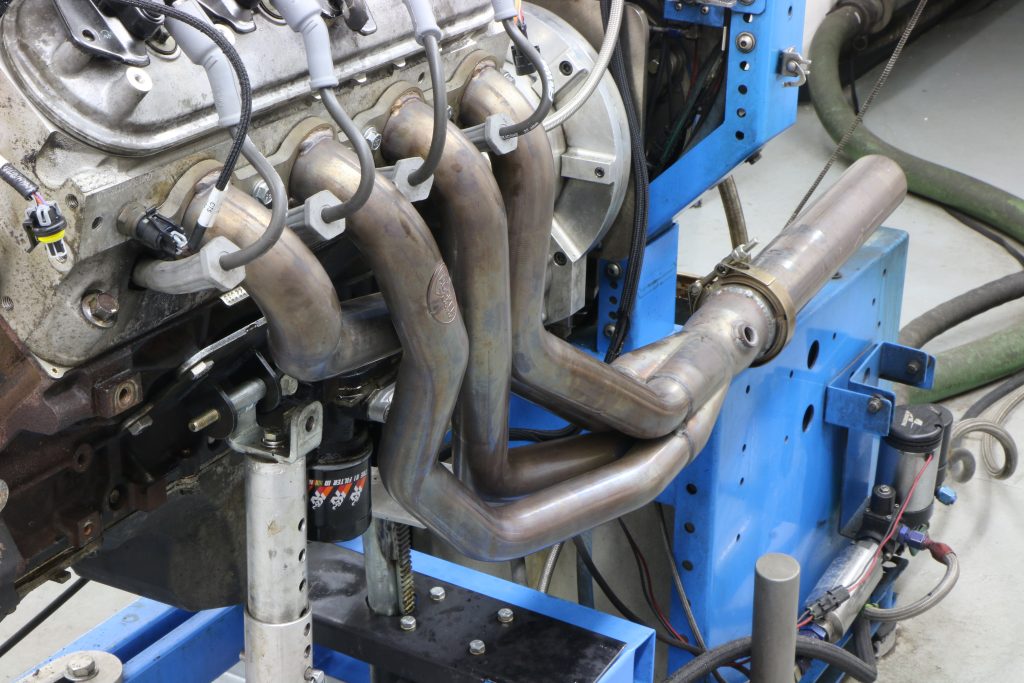

Run with 1-7/8 inch, long-tube headers, the cammed LY6 produced 514 hp at 5,900 rpm and 493 lb.-ft. of torque at 4,600 rpm.

If you’re seeking to exceed 500 hp with inventory cathedral-port heads (we examined 799s on this LY6), it takes a much bigger, extra aggressive cam to offset the change in head circulate (rectangular ports circulate close to 310 cfm, 799s circulate close to 250 cfm).

Run with a Comp 469 cam (617/624, 231/247, 113), 799 heads, and Dorman LS2 consumption, the 6.0L produced 524 hp and 485 lb.-ft. of torque. Run with this identical cam and the rec-port heads, the LY6 produced 543 horsepower—so head circulate is each bit as vital as cam timing, however now how will we get to 600 hp?

600 Horsepower 6.0L LQ4/LQ9

Coaxing over 500 hp out of your 6.0L will not be terribly tough, neither is 550 hp—however while you beginning asking the motor to eclipse 100 hp per liter (over 1.64 hp per inch), issues get tougher.

To achieve this quantity, you want extra of every part, together with head circulate, cam timing, and the best consumption manifold.

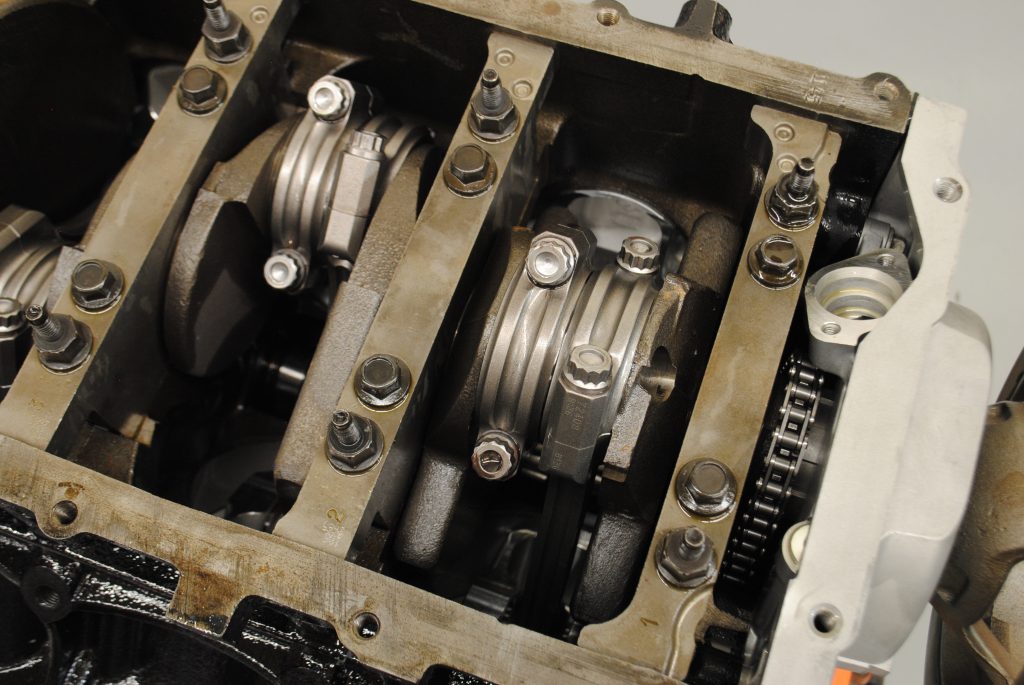

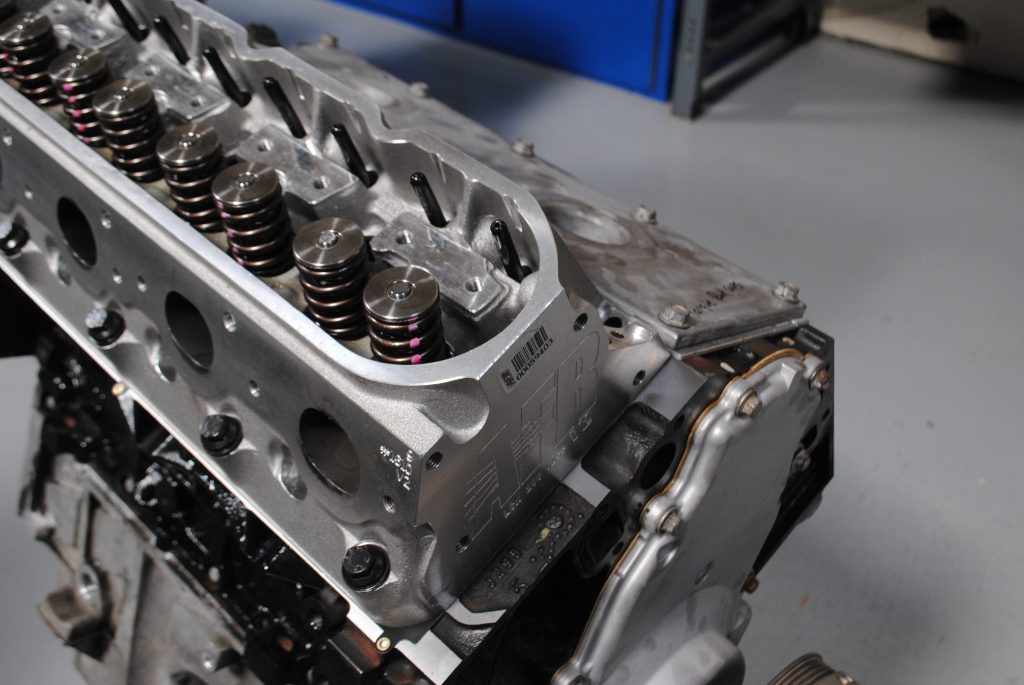

The 600 hp 6.0L not solely obtained this stuff, however began out life as an entire construct up. The place the 400 hp and 500 hp model required nothing greater than inventory backside ends, the 600 hp 6.0L featured solely a inventory iron block and solid crank. To those we added solid 6.125 inch rods and solid flat-top pistons that had beneficiant valve reliefs that offered enough piston-to-valve clearance to permit for the required wilder cam timing.

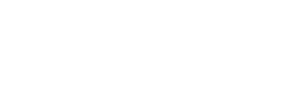

Comp Cams equipped the required stick, with specs of 0.624 elevate, a 239/255 diploma period break up, and 114 diploma LSA. The cam was mixed with a set of AFR LSX 230 V2 heads that offered peak circulate numbers of 328 cfm on the consumption and 252 cfm on the exhaust. High quality cylinder heads make reaching your energy aim a lot simpler. The ending touches included a Quick LSXRT consumption and 102mm throttle physique, 1 7/8-inch headers and our Holley HP ECU.

Run on this method, the 6.0L produced 596 hp and 501 lb.-ft. of torque.

What wouldn’t it take to get the additional 5 or 6 horsepower to exceed 600 hp you ask? Simply set up a brief runner consumption (assume BTR Trinity) and you’ll actually see 600 hp numbers, although torque manufacturing will endure.

[ad_2]