[ad_1]

Infineon Applied sciences has developed the world’s first 300 mm gallium nitride (GaN) wafer know-how, marking a major milestone within the energy semiconductor trade. By leveraging its current 300 mm silicon manufacturing infrastructure, Infineon has created a scalable, high-volume manufacturing course of that enhances cost-efficiency.

The 300 mm GaN wafers supply 2.3 occasions extra chips per wafer in comparison with 200 mm wafers, enhancing manufacturing effectivity and gadget efficiency. This innovation positions Infineon as a frontrunner within the quickly rising GaN market, which is projected to succeed in a number of billion {dollars} by the top of the last decade.

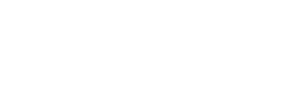

Infineon CEO Jochen Hanebeck showcases one of many first 300 mm GaN energy wafers, produced in a scalable high-volume manufacturing setting. (Picture: Infineon)

GaN-based energy semiconductors are gaining traction throughout numerous sectors, together with industrial, automotive, client electronics, AI energy provides, photo voltaic inverters, and motor-control methods. GaN know-how provides vital benefits, comparable to elevated vitality effectivity, diminished dimension and weight, and decrease total prices for finish customers. The brand new 300 mm GaN wafers guarantee larger provide stability and scalability, making them ultimate for rising market calls for.

Infineon’s integration of 300 mm GaN wafers into its current silicon manufacturing strains in Villach, Austria, demonstrates the corporate’s experience in each GaN and silicon-based semiconductors. This breakthrough additionally paves the best way for price parity between GaN and silicon, notably when it comes to comparable R DS(on) ranges. Infineon goals to showcase the primary 300 mm GaN wafers on the electronica commerce present in November 2024 in Munich.

A technical engineer in Infineon Applied sciences’ cleanroom in Villach, Austria, holds a 300 mm gallium nitride wafer. (Picture: Infineon)

This development reinforces Infineon’s management in energy methods and its dedication to innovation, notably within the fields of decarbonization and digitalization. The corporate’s strategic concentrate on GaN, alongside silicon and silicon carbide, highlights its place on the forefront of semiconductor know-how.

Filed in . Learn extra about Infineon and Semiconductors.

[ad_2]