[ad_1]

To develop extra environment friendly e-motors, OEMs and suppliers

should innovate, steadiness design management with outsourcing, and handle

provide chain dangers.

The electrical motor (e-motor) market is forecasted to extend

quickly over the subsequent decade. Extra environment friendly electrical propulsion

applied sciences just like the eAxle and its elements drive this

progress.

With main markets like India aiming to affect its

transportation, how will unique gear producers (OEMs)

steadiness design and expertise must sustainably supply and

produce eAxles at scale?

Innovation in motor design and energy

The eAxle is a compact, built-in meeting that mixes the

motor, energy electronics, and transmission important to an electrical

automobile's (EV) infrastructure. S&P World Mobility estimates

over 122 million e-motors will probably be produced by 2035, with over 70%

of them utilizing eAxles, pushed by developments in energy density and

effectivity.

Specifically, e-motor designers concentrate on attaining increased

particular energy, which measures the facility output per unit of weight.

Excessive particular energy provides higher energy output in a lighter and

smaller motor. This phenomenon interprets to improved power

effectivity, extra prolonged vary, and higher total system

efficiency for an EV.

Energy tendencies present a median enhance in particular energy by 35%

from one technology to a different. This pattern is the results of

modern methods by suppliers like Bosch, Valeo, and others

that both concentrate on augmenting energy whereas sustaining weight,

lowering weight whereas protecting energy fixed, or ideally attaining

features in each energy and weight concurrently. It will likely be incumbent

upon producers to know the trade-offs and select the

eAxle configuration for his or her particular use case.

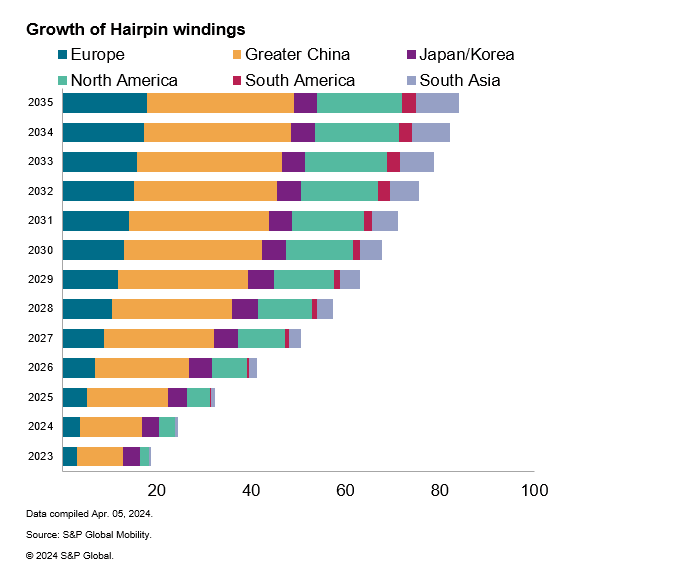

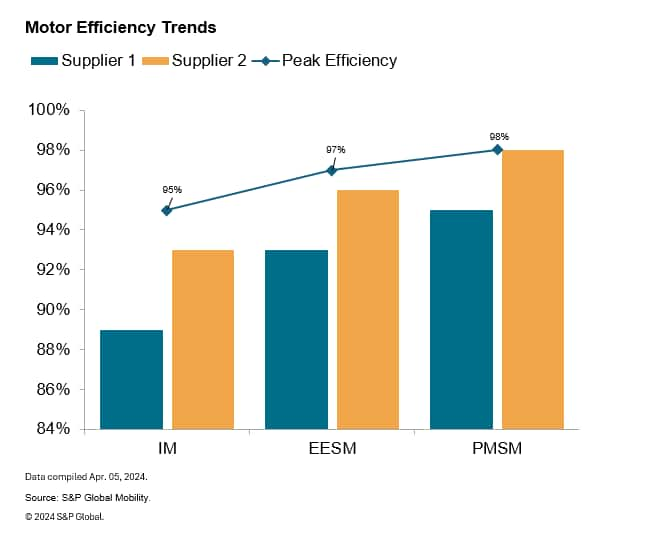

System designers have additionally made progress in enhancing motor

pace. S&P World Mobility forecasts that 19% of the Indian

market demand by 2035 will probably be for motors able to working at

speeds above the 20,000 RPM restrict. Producers prioritize

high-performance winding applied sciences like hairpin winding to

obtain extra thermally environment friendly and power-dense motors able to

sustaining these increased speeds.

Winding expertise, which entails arranging coils inside the

motor, is an important think about optimizing motor efficiency,

effectivity, and energy density. A hairpin winding design is

most popular because it minimizes losses and maximizes fill issue – the

ratio of the quantity of copper wire used within the winding to the whole

out there house inside the stator.

Motor effectivity tendencies

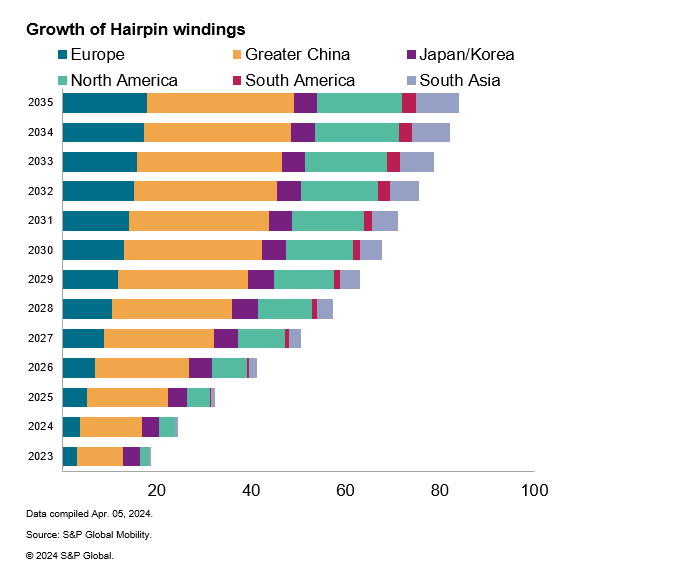

Everlasting Magnet Synchronous Motors (PMSMs) have emerged because the

business normal among the many completely different motor sorts as a result of their

superior effectivity and energy density. These attributes make them

extremely appropriate for electrical automobiles the place efficiency and vary

are vital. Nonetheless, their reliance on uncommon earth supplies,

vital for his or her sturdy magnetic fields, poses price and moral

sourcing challenges.

The business is exploring alternate options to PMSMs, similar to

induction and externally excited motors, which don’t require uncommon

earth parts however might have various weight, energy, and effectivity

trade-offs. As an example, Tesla is creating a uncommon earth-free

magnet that targets lower-cost automobiles. Different OEMs, similar to GM and

Stellantis, additionally make investments on this space.

The worldwide shift in the direction of sustainability can be influencing the

manufacturing of motors. Whereas PMSMs will proceed to dominate the

market, there’s a noticeable pattern in the direction of non-magnet-based

motors, that are forecasted to represent 23% of the worldwide market

by 2035. OEMs are eager to scale back dependency on neodymium, a uncommon

earth component utilized in everlasting magnets, which often

fluctuates in availability and value. By lowering the usage of

neodymium in motors, producers can cut back prices and improve

sustainability.

Main automotive gamers are investing in recycling and

sustainable supplies to scale back their merchandise' environmental

impression additional. Copper is a vital materials in motor development

and meeting. With developments in wire expertise, such because the

transition from spherical to rectangular wires, producers optimize

copper utilization, main to higher effectivity and diminished

materials use.

Mainland China is the main world provider of e-motors as a result of

its considerable reserves of uncommon earth parts. Nonetheless, investments

in materials partnerships are reshaping the EV motor manufacturing

panorama. For instance, BMW iVentures' funding in uncommon earth

component recycling and Niron Magnetics' improvement funding for

clear earth magnets are simply a number of the efforts to innovate and

safe provide chains within the EV sector. As main OEMs look to

diversify provide away from mainland China, India stands to achieve.

Nidec and ZF have invested in new crops in Karnataka and Orgadam

to extend manufacturing.

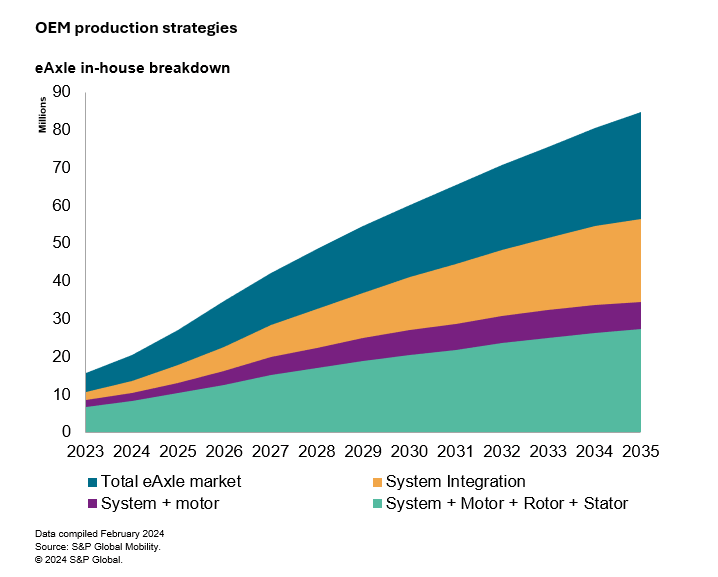

As EV adoption grows, the eAxle in-house manufacturing ranges

more and more point out OEMs' technique to combine design and

management manufacturing. By 2030, 68% of eAxles will outcome from

in-house OEM system integration.

This transition, nonetheless, is just not devoid of challenges. With

rising volumes, OEMs should diversify the availability chain and

doubtlessly depend on outsourcing for particular manufacturing processes.

By so doing, OEMs can then concentrate on system integration whereas

leveraging the experience of specialised suppliers.

The regional dynamics of eAxle manufacturing can range relying on

technological capabilities and provide chain constraints. Fairness

alliances are extra favored in areas like Japan and Korea, whereas

North America prioritizes in-house manufacturing. By 2030, the

in-house manufacturing of techniques that embrace motor and rotor or

stator elements will decline to 34%, marking a strategic reliance

on provide chain partnerships to optimize manufacturing effectivity and

price.

Because the EV market matures, effectivity is the central theme, not

simply within the electrical motors however throughout your entire provide chain,

from uncooked supplies to closing meeting. It would take innovation,

strategic materials sourcing, and manufacturing effectivity from

automakers, suppliers, and OEMs to drive the way forward for electrical

mobility.

This text is a part of a sequence that includes

highlights from S&P World Mobility's 2024 Options Webinar

Sequence. The E-Motor Know-how and Provide Chain Evolution webinar

occurred on April 16, 2024.

Register for upcoming webinar

periods

[ad_2]