[ad_1]

It’s straightforward to seek out or construct large horsepower nowadays. It’s additionally straightforward for even seasoned automobile people to get into bother by constructing a too-radical mixture. Admittedly, I’m one in all them.

Is it potential to tame the beast in an effort to at the very least drive and luxuriate in it? The reply is totally sure. We put collectively an inventory of 10 methods to take action. The ideas are based mostly upon tuning changes in addition to easy engine components adjustments you can also make. None of them require you go deep contained in the engine or make main adjustments like a head or camshaft swap.

Right here they’re in no specific order:

Tip 1: Smaller Carburetor

In lots of conditions, a giant carburetor is critical to make horsepower, however you’ll be able to the truth is make good energy with a smaller carburetor. Contemplate an L88 Corvette in NHRA Tremendous Inventory, working both SS/AA or SS/BA. A few of these automobiles can produce within the space of two horsepower per cubic with a single OEM 850 CFM manufacturing line carburetor. We all know of a racer with a 1969 427 Corvette working within the 8.70-second vary at authorized “A” weight.

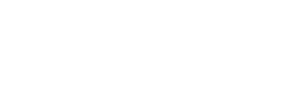

One other instance: I take advantage of a 950 CFM Holley Extremely XP carburetor on a 565 cubic inch large block Chevy. It will make extra energy with one thing like an 1,150 CFM Dominator, however the smaller carb helps driveability enormously (and I in all probability don’t want any extra energy!).

Tip 2: Carburetor Spacers

Twin aircraft consumption manifolds can enhance backside finish energy on an in any other case prime end-biased engine mixture. However what if in case you have a single aircraft? Again within the day there have been carburetor spacers with plenum dividers to assist a single aircraft consumption mimic a twin aircraft, however they’re not straightforward to seek out at present. An alternate is a four-hole spacer just like the HVH “Tremendous Sucker”. Obtainable in heights from a 1/2-inch to 2 inches tall, the spacers have a tapered design that may enhance torque and throttle response on many single aircraft engine functions.

Tip 3: Spark Plug Hole

Relying on combustion chamber measurement and different components, some engine mixtures will decide up a little bit of throttle response with a bigger spark plug hole. NGK weighs in on this:

“The voltage requirement is instantly proportional to the plug’s hole measurement. The bigger the hole, the extra voltage is required to leap it. Most skilled tuners know that rising the hole measurement will increase the spark space uncovered to the air-fuel combination, which maximizes burn effectivity. Because of this, most racers add high-energy ignition techniques. The added power permits them to extend the hole, however nonetheless have sufficient voltage to leap it.”

“Nevertheless, if the hole is simply too giant and the ignition system can’t present the voltage wanted to spark throughout the hole or turbulence within the combustion chamber blows out the spark, misfires will happen. These with modified engines should keep in mind that increased compression or pressured induction will sometimes require a smaller hole setting to make sure ignitability below increased strain.”

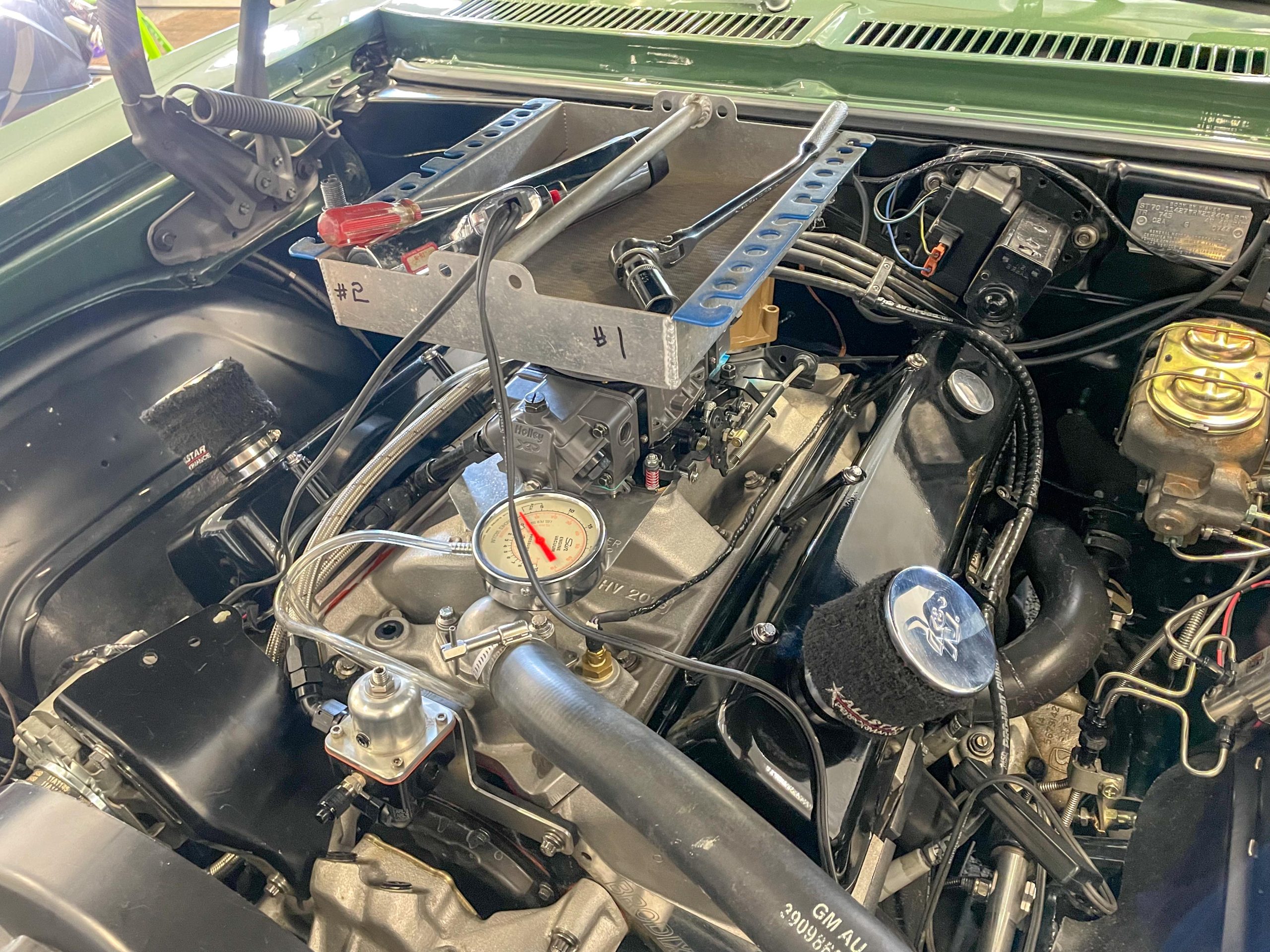

Tip 4: Valve Lash

On most engines with stable cams, it’s potential to mess around with valve lash to idiot the engine into pondering it has a smaller camshaft. Loosening the valve lash makes the cam seem smaller, which in flip helps backside finish efficiency. Tightening the valve lash makes the cam seem bigger, which helps on the highest finish.

Most folk make lash adjustments in 0.002-inch increments. The late nice Harold “UltraDyne” Brookshire as soon as informed me that about 0.006-inch of lash equalled roughly 4 levels distinction in period (relying on the cam’s ramp design). In any case, it’s finest to not go too far on valve lash adjustments. Sometimes, 0.008- to 0.010-inch or much less is the max you’ll be able to deviate from the producer’s specs. Run a cam too unfastened or too tight and also you’ll run into issues.

Tip 5: Preliminary Advance

Loads of modified engines don’t run sufficient preliminary ignition advance. Many muscle car-era mixtures had manufacturing unit preliminary advance settings of 4 or 5 levels, which will not be adequate for a modified engine. An preliminary setting of 10-12 levels (in some circumstances with a giant dome piston, much more) could also be required.

To get there, you’ll must shorten the advance curve so you might have extra complete ignition advance. Most frequently that is achieved with elevated diameter advance bushing stops (most good curve kits embrace these) or by welding the slots within the advance weights. If the automobile has an automated transmission, strive making the curve tremendous brief and fast. You is perhaps shocked on the outcomes.

Tip 6: Rocker Arm Ratio

You probably have an engine with a giant cam, take into account lowering the rocker arm ratio. Swapping rockers is way simpler than swapping out a camshaft, plus a lower in rocker ratio simply would possibly enhance valvetrain reliability.

For instance, the camshaft in my Nova has an consumption valve raise of 0.765-inch with a 1.7:1 rocker ratio. If I swapped out the rockers for a set of 1.6:1 rockers, the efficient valve raise would work out to 0.720-inch. The smaller rocker arm ratio with additionally make the cam act “smaller” on the period aspect of the equation. That simply would possibly show to be the ticket for taming it.

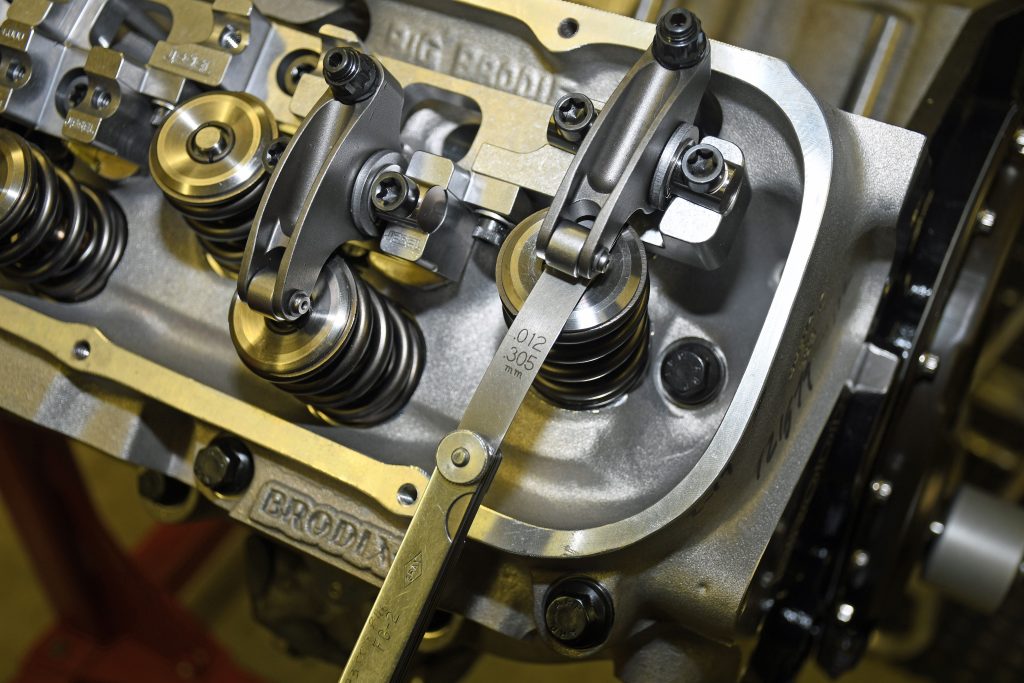

Tip 7: Accelerator Shooter Tuning

Establishing accelerator pump shooters (aka accelerator pump discharge nozzles) correctly in a Holley carburetor is essential, particularly when coping with grumpy engine mixtures. Used to tune off-the-line acceleration, the shooters are positioned in the primary physique of the carburetor within the venturi space.

If preliminary acceleration produces a hesitation after which picks up, the shooter measurement should be elevated. In sure circumstances, the accelerator pump shooter could also be so small (lean) that the engine will backfire throughout acceleration. If the shooter is simply too giant, off-idle acceleration won’t be crisp or clear. Generally the automobile will launch cleanly however then nostril over. That’s additionally a sign the shooter is simply too giant. It would typically create a puff of black smoke throughout acceleration.

A quite common tuning false impression issues an engine bathroom or hesitation simply off idle. Novice tuners typically assume the bathroom is created by extra gasoline so that they lean out the carburetor jetting. That is incorrect! Though it could initially appear as if far an excessive amount of carburetion, the bathroom is definitely created by too little gasoline. As air flows into the engine because the throttle is cracked open, there may be inadequate gasoline to cowl up that “air gap”. The repair is easy: maintain rising the accelerator pump shooter measurement till the bathroom is cured. In the long run, shooter choice is a trial-and-error job that’s tuned by experimenting.

Tip 8: 50cc Accelerator Pump Package

If you find yourself needing an accelerator pump shooter bigger than a #37, it’s probably time to step as much as a 50cc accelerator pump meeting. The usual accelerator pump has a 30cc capability. Pump capability is set by amassing the quantity of gasoline produced by 10 full strokes of the pump. In consequence, every stroke of a typical accelerator pump delivers 3cc of gasoline whereas every stroke of the bigger pump delivers 5cc of gasoline.

Accelerator pump measurement turns into crucial in radical mixtures. The bigger the carburetor in relation to engine displacement and engine velocity, the extra want for a bigger pump shot. The additional the carburetor is away from the consumption valve—an engine with a tunnel ram consumption, for instance—the extra want for a bigger pump shot. That is fairly essential with automated transmission mixtures.

A great instance is a closely modified engine that has to haul round a heavy automobile with a tall rear axle ratio. It could generally develop a extreme stumble. If rising the shooter measurement and revising the pump cam timing doesn’t work, you’ll have to extend the scale of the accelerator pump.

It’s fairly widespread to make use of a 50cc accelerator pump equipment on each the first and secondary aspect of the carb in automated transmission drag race functions. When utilizing a 50cc pump equipment, all the time verify the clearance between the pump and the consumption manifold. Generally you’ll be able to flippantly grind the consumption. In different circumstances, you is perhaps pressured to make use of a small carb spacer to offer the required clearance.

Tip 9: Accelerator Pump Cam Tuning

We’re not fairly achieved with accelerator pump tuning. Holley affords an assortment of accelerator pump cams, every with a selected raise and period profile. Brown and yellow pump cams are designed to be used with 50cc pumps whereas the opposite color-coded cams can be utilized with normal 30cc pumps.

The pump cam has a direct impact upon the motion of the accelerator pump lever, which controls the timing and to a lesser diploma the quantity of gasoline obtainable on the shooter. A cam with a pointy (aggressive) lobe profile supplies sturdy pump motion and faster strain rise. A softer nostril cam with a less-aggressive lobe profile has the alternative impact.

Putting in a pump cam is simple as loosening a screw, inserting it subsequent to the throttle lever, and tightening it up. Every cam has two (and in some circumstances three) numbered holes. With a gentle mixture that idles at decrease speeds–say 600 or 700 RPM–you’ll discover place primary useful. That’s as a result of it’s going to have an honest pump shot coming proper off idle.

Positions quantity two and quantity three delay the pump shot barely. They supply the additional throttle opening required to keep up increased RPM idle speeds (1,000 RPM and better). As soon as you alter the pump cam or change the pump cam place, it’s best to recheck the pump arm clearance.

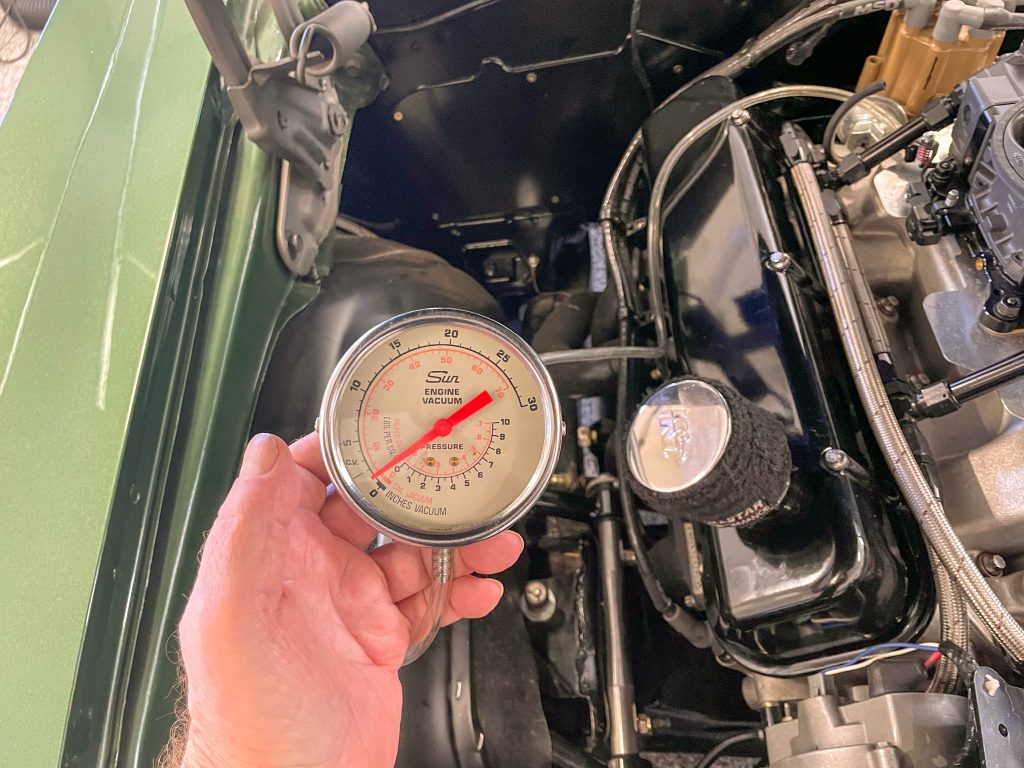

Tip 10: Vacuum Gauge Carb Tuning

A vacuum gauge could possibly be your finest good friend in terms of setting carburetor idle combination. It’s notably essential in functions like those we’ve been speaking about. Normally, engines with large cams don’t have a lot vacuum to start with, and a gauge actually helps you dial within the little vacuum they’ve.

Right here’s the way it works: With the gauge attached, go to the first aspect of the carburetor and set every idle combination screw till the vacuum gauge reads the best degree. You’ll have to shuttle between the combination screws a few instances to succeed in that time. If the carburetor has secondary combination screws, repeat the method. You might need to return to the primaries and readjust the idle combination after adjusting the secondary screws. Whenever you’re achieved, enrichen every of the combination screws barely. When you’re achieved, you’ll probably must reset the idle velocity.

[ad_2]